Following the shell shock from COVID-19 nearly halting American productivity, dilemmas like how to social distance employees and shore up wabbling supply chains came into view. Months later, the pandemic is still disrupting manufacturing frameworks that had been adequate in a pre-COVID world, and consumer demand continues to spike, especially for products that facilitate more time at home. That has separated the companies prepared to adapt and absorb the demand from those still grappling to meet the challenge.

Companies unready to make operational changes during initial coronavirus uncertainty now seek robotics to facilitate growth and keep employees safe. As history shows, it’s the most adaptive organizations - not necessarily the oldest or largest - that survive large-scale industry disruptions.

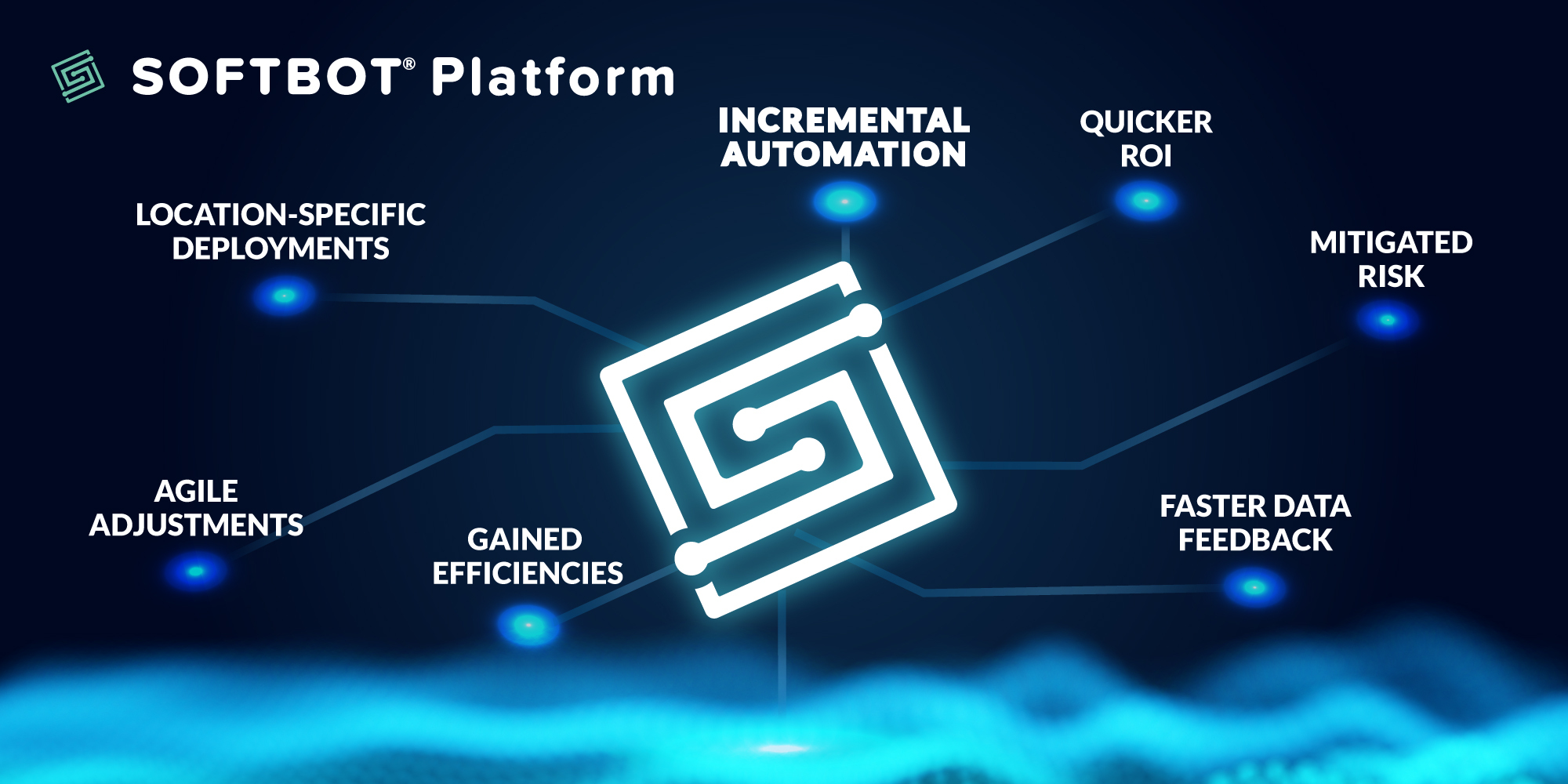

That has set in motion the trend for more companies to invest in automation or step up their plans to do so. When correctly deployed, advanced technologies like automation, AI, and interoperability can help companies meet spikes in demand and keep workforces safe. Businesses can build flexibility and adaptability into their operational workflows to mitigate risk while maintaining peak efficiency in times of shifting markets.

But robotics isn’t typically plug-and-play automation, and even adding new technology to an existing system can be as challenging as starting from scratch. Process and enterprise software integration can take months or even years. Yet now, more than ever, fast adoption and integration of robotics is critical.

How can companies classified as the “late majority” in the robotics market catch up?

To dive deeper into this topic, we took the discussion to SVT Robotics VP of Customer Success and Growth, TJ Fanning, and Vecna Robotics Chief Revenue Officer, David Clear. In this informative podcast, TJ and David weigh in on automation industry trends and the strategies companies should consider to quickly meet shifting market needs and consumer demand.

You’ll learn:

- What high-speed integration is and how it can be deployed without custom code

- How AMRs can create a more resilient and flexible manufacturing operation

- How flexible automation can mitigate risk for manufacturing and other industrial organizations

- Automation and robotic trends in manufacturing

.jpg)